Steam Turbine Gland Sealing System Explained: A Beginner’s Guide for Power Engineers

Introduction: What Exactly Is a Gland Sealing System?

I still remember my first week as a junior engineer when I heard this odd hissing sound near the turbine. My supervisor just said, “Welcome to the world of gland sealing problems!” That little lesson cost us about $50,000 in lost efficiency that month – and taught me why understanding gland sealing systems isn’t just academic knowledge, it’s money in the bank.

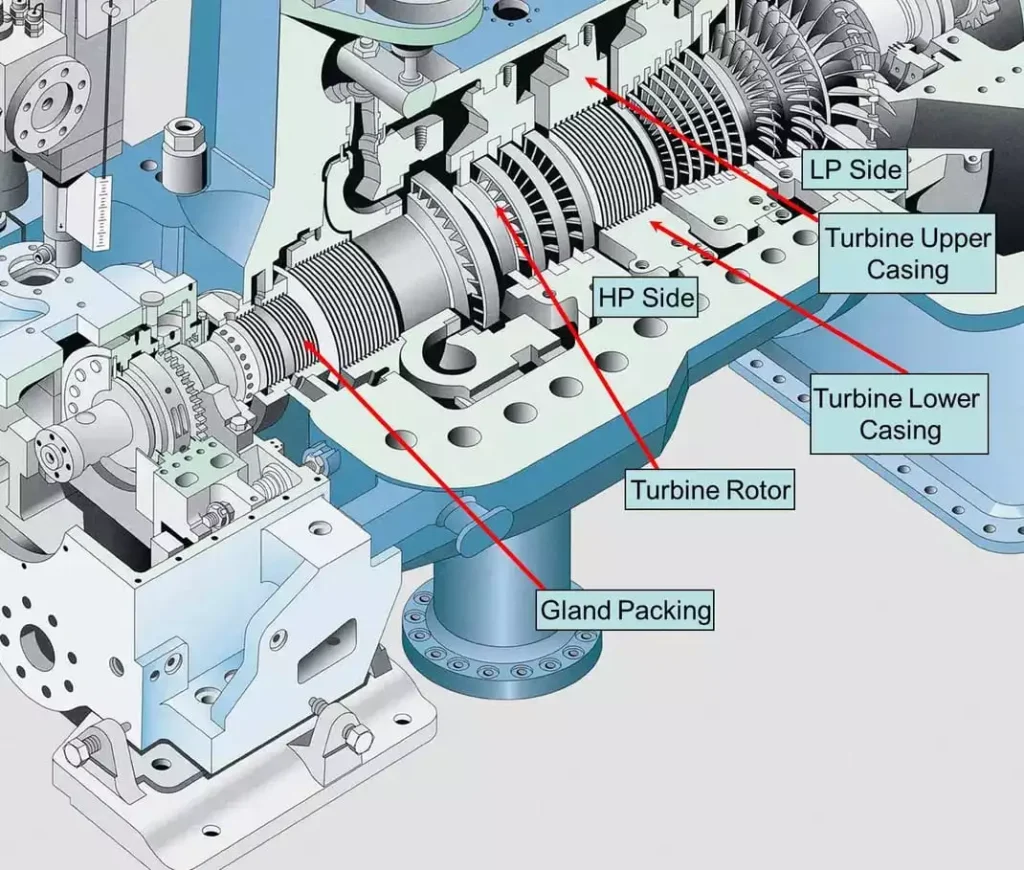

So what exactly is a gland sealing system? Simply put, it’s the mechanism that seals the small gap between the rotating turbine shaft and the stationary turbine casing. Why does that matter? Because inside the turbine casing, you have high-pressure, high-temperature steam, and that steam wants to escape wherever it can. If not sealed properly, it will leak out along the shaft—and that leads to several serious issues.

Think of it like this: imagine a rotating rod passing through a pressure cooker. If you don’t seal the spot where the rod enters the cooker, steam will start hissing out. Not only is it inefficient, it’s also dangerous. The same principle applies in turbines, just on a much larger and more complex scale.

Here’s what I’ve learned happens when these seals go bad. First, you start hemorrhaging steam, which is literally money flowing out into the atmosphere. I’ve watched plants lose 2-3% efficiency just from poor gland sealing. Then there’s the safety aspect. Steam leaks create hot spots that can seriously burn someone, and they fog up the turbine deck so badly you can’t see what you’re doing. Plus, your environmental folks won’t be happy when you’re venting steam to atmosphere.

In this guide, I’ll walk you through everything I wish someone had explained to me when I started – basic types of gland sealing systems, how gland steam sealing works, normal operation of gland steam sealing, and the maintenance tricks that’ll keep your plant manager smiling. We’ll keep it practical, because at the end of the day, understanding this stuff makes you a better engineer and keeps everyone safer.

Why Do Steam Turbines Need Gland Sealing System?

The Basic Problem

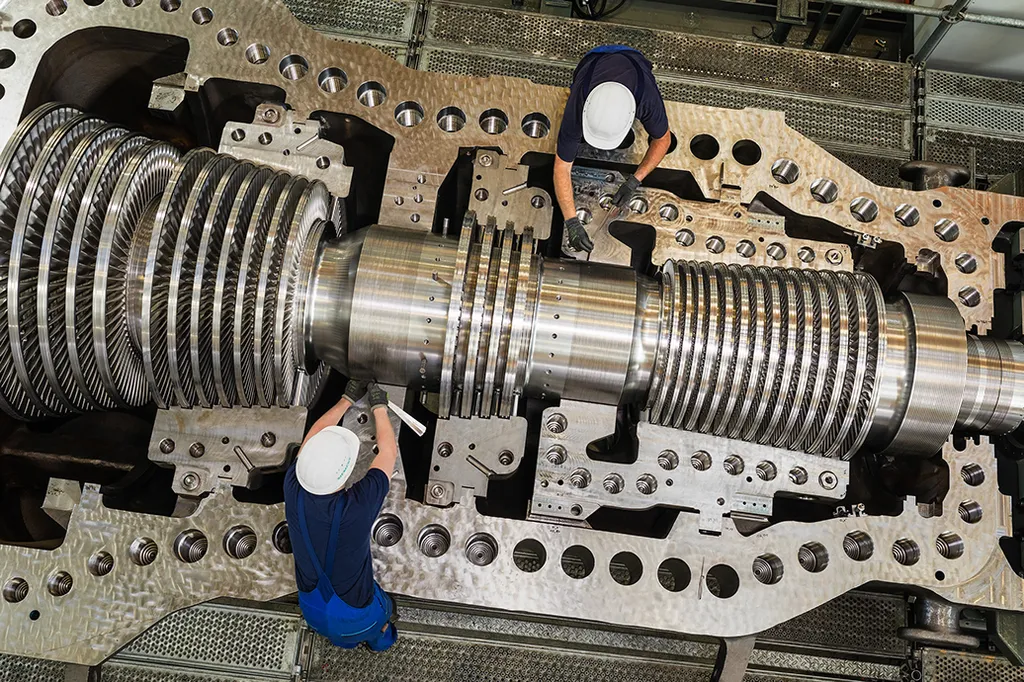

Let me paint you a picture of what we’re dealing with here. Inside your turbine, you’ve got steam at maybe 2,400 psi and 1,000°F – that’s enough pressure to blow a manhole cover three blocks away and hot enough to turn water into steam instantly. This steam needs to push against your turbine blades to generate power, but here’s the catch: your rotor shaft has to come out of the casing somehow to connect to the generator.

Think about it – you’ve got this perfectly sealed pressure vessel, except you need to punch holes in it for the shaft to pass through and rotate freely. That creates a challenge: how do you contain high-pressure steam while allowing the shaft to rotate? This is where shaft penetrations—the points where the shaft exits the turbine casing—become potential leak paths where Mother Nature tries to equalize pressure, and she doesn’t care about your plant economics.

The main leak points I always tell new guys to watch are the high-pressure and low-pressure shaft seals. On the HP end, you’re dealing with the nastiest conditions – maximum pressure and temperature. On the LP end, you might think it’s easier, but you’re often dealing with vacuum conditions that want to suck air in, which brings its own problems. I’ve seen plenty of experienced engineers get caught off guard by LP seal issues because they underestimated the challenge.

Consequences of Poor Sealing

Here’s where the rubber meets the road – or should I say, where the steam meets your profit margin. Every pound of steam that leaks out is energy you’ve already paid to create but aren’t getting any work from. I ran the numbers once on a 500 MW unit, and just a 1% steam leakage rate was costing us about $200,000 per year in lost fuel. That’s real money, not some theoretical calculation.

But the financial hit is just the beginning. I’ve seen steam leaks create 400°F hot spots on turbine casings that’ll give you third-degree burns faster than you can say “workman’s comp claim.” The worst part? These leaks create steam plumes that turn your turbine deck into a fog bank. Try troubleshooting equipment when you can’t see your hand in front of your face – it’s not fun, and it’s definitely not safe.

Then there’s what we call “steam cutting” – when high-velocity steam acts like a sandblaster on your equipment. I’ve seen steam leaks carve grooves in steel casings over time, turning a simple seal replacement into a major repair job. What can have been a $5,000 maintenance job becomes a $200,000 overhaul.

What Good Sealing Achieves

When your gland sealing system is working properly, it’s like having a good insurance policy – you don’t think about it much, but it’s protecting everything you care about. First and foremost, you’re keeping that expensive steam where it belongs – doing work instead of heating up the atmosphere.

Good sealing also means your operators can actually see what they’re doing and walk the turbine deck safely. No more dodging steam plumes or worrying about getting scalded during routine inspections. Your maintenance guys will thank you too – there’s nothing worse than trying to work on equipment while steam is hissing all around you.

Finally, and this is something that took me years to fully appreciate, proper sealing extends the life of everything around it. Steam leaks don’t just waste energy – they create corrosive environments, thermal stress, and moisture problems that can shorten the life of expensive equipment. Fix your sealing, and suddenly your turbine casings, piping supports, and instrumentation last longer. It’s one of those investments that keeps paying dividends for years.

Basic Types of Gland Sealing

Gland Steam Sealing (Most Common)

I can tell you that about 90% of the units I’ve encountered use gland steam sealing as their primary method. Why? Because it’s elegant in its simplicity – we use steam to seal against steam.

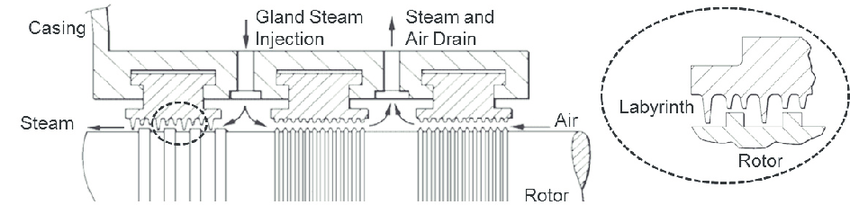

Here’s how it works: imagine you’re trying to stop water from flowing out of a pipe by introducing water from the side at just the right pressure. The gland steam system does exactly that with steam. We inject clean, controlled steam at a slightly higher pressure than what’s trying to leak out, creating what I like to call a “steam curtain” around the shaft.

The beauty of this system is in the pressure balance. Think of it like two people pushing against each other – if the gland steam pressure is just a bit higher than the turbine steam pressure, the gland steam flows inward and prevents the turbine steam from escaping. The key word here is “just a bit” – too much pressure and you’re wasting steam, too little and you get leakage.

This method is popular because it’s self-regulating to some extent. As turbine conditions change during startup or load variations, the pressure differential adjusts naturally. Plus, steam is already available in the plant, so you’re not introducing foreign materials or complex mechanical systems.

Mechanical Seals

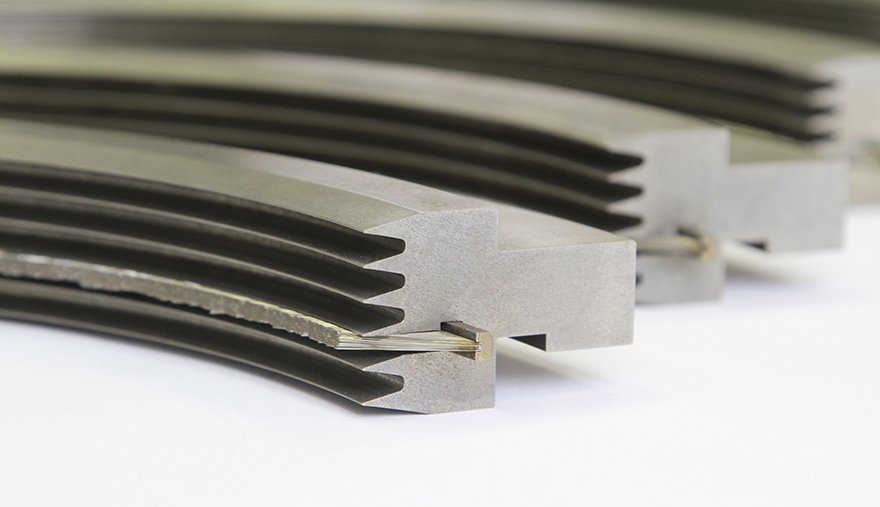

Now, there are times when steam sealing isn’t practical or desirable, and that’s where mechanical seals come in. The most common type I’ve worked with are carbon ring seals – essentially spring-loaded carbon rings that press against a smooth collar on the shaft.

These are typically used in smaller turbines, special applications where you can’t afford any steam leakage at all, or in sections where steam isn’t readily available. I’ve seen them used effectively on extraction turbines where you need absolute control over what goes where.

The advantage is obvious – zero steam consumption for sealing, and they work regardless of pressure conditions. But here’s the catch: they’re maintenance-intensive. Those carbon rings wear out, they’re sensitive to shaft runout, and if your shaft gets a scratch or deposits, you’re looking at expensive repairs. I always tell operators that mechanical seals are like a high-performance sports car – great when they work, but they need more attention than your average system.

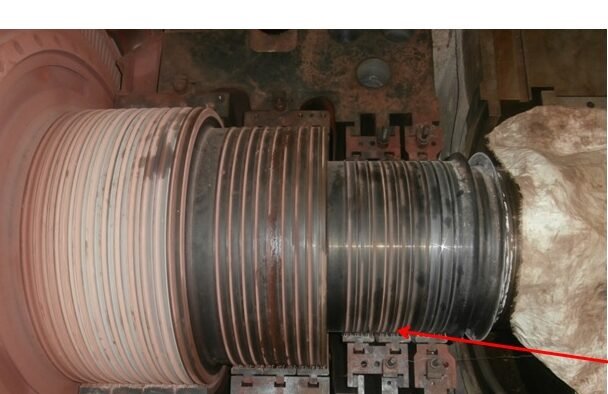

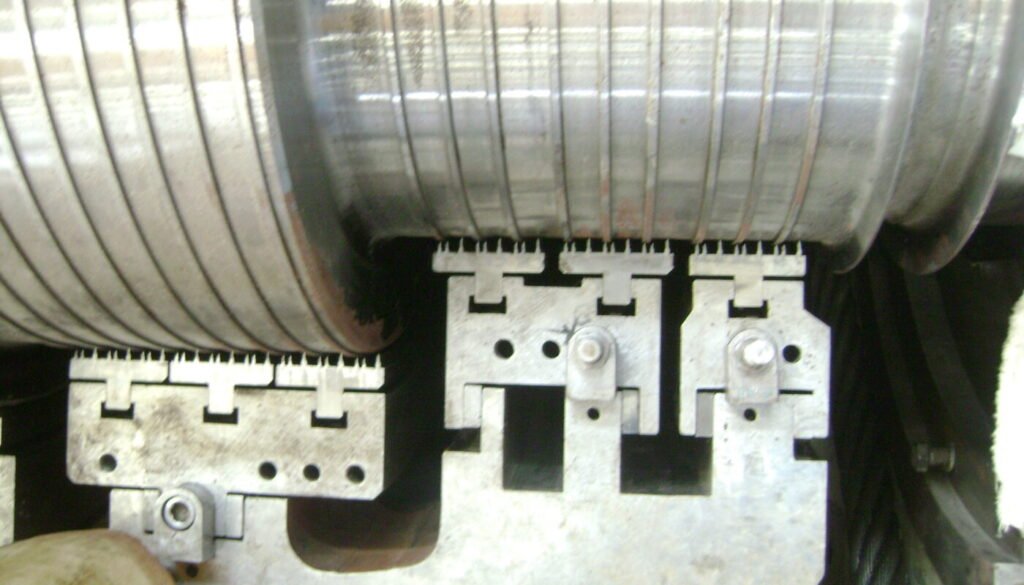

Labyrinth Seals

Labyrinth seals are the workhorses that often go unnoticed because they’re usually working alongside other sealing methods. Think of them as a series of speed bumps for steam flow – each restriction doesn’t stop the flow completely, but together they create enough pressure drop to significantly reduce leakage.

Picture a shaft with a series of fins or ridges machined into it, running inside a casing with matching grooves. Steam trying to leak past has to navigate this maze, losing pressure and velocity at each restriction. It’s like trying to pour water through a series of funnels – each one slows down the flow.

I’ve found these work best when combined with gland steam sealing. The labyrinth seals do the heavy lifting of pressure reduction, while the gland steam provides the final barrier. In many modern turbines, you’ll see labyrinth seals creating multiple pressure zones, with gland steam injection at strategic points between them.

How Gland Steam Sealing Works

The Basic Principle

Let’s dig deeper into how gland steam sealing actually works, because understanding this will help you troubleshoot problems and optimize performance. The fundamental principle is pressure differential – we’re creating a zone around the shaft where our controlled gland steam pressure is slightly higher than whatever pressure is trying to leak out.

The “steam curtain” concept is crucial here. We’re not creating a solid barrier– we’re creating a flowing boundary of steam that acts like a pressure wall. This curtain needs to be maintained continuously, which is why gland steam systems run all the time the turbine is operating, not just during startup.

The pressure balance is delicate. I’ve seen operators crank up gland steam pressure thinking more is better, only to waste thousands of pounds of steam per hour. The sweet spot is usually just 2-5 psi above the pressure you’re sealing against. Too much higher and you’re pushing excessive steam into areas where it doesn’t belong.

Where Sealing is Needed

Every turbine is different, but there are common locations where you’ll always need sealing. The high-pressure turbine inlet is the most critical – this is where you have maximum pressure and temperature trying to escape.

On multi-pressure turbines, you’ll have sealing points between each pressure zone. These intermediate seals prevent steam from the higher pressure sections from flowing backward into lower pressure areas. It’s not just about preventing leakage to atmosphere – it’s about maintaining the pressure profile that makes the turbine work efficiently.

The low-pressure sections present a different challenge. Many LP turbines operate under vacuum, which means you’re not just preventing steam from getting out – you’re preventing air from getting in. Air infiltration kills turbine efficiency faster than most other problems, so LP gland sealing often involves creating a slight positive pressure barrier.

If your turbine drives a generator directly, you might also need sealing at the generator end, especially if the generator is hydrogen-cooled. Nobody wants steam mixing with hydrogen – that’s a conversation with the safety department you really don’t want to have.

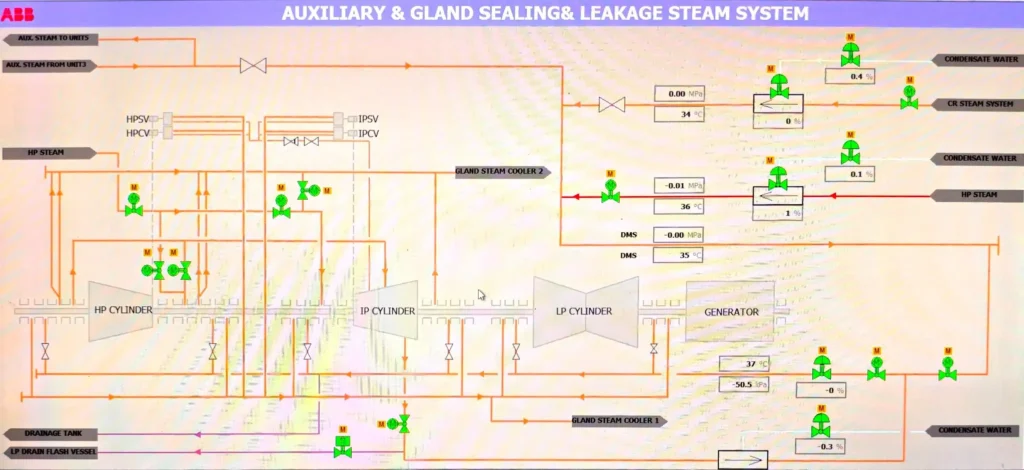

Steam Source and Supply

Gland steam has to come from somewhere, and where it comes from matters more than you might think. In most plants, gland steam comes from either the auxiliary boiler during startup or from an extraction point on the main turbine during normal operation. Some plants use steam from the main steam header, but that’s usually overkill.

The key is pressure control. Gland steam pressure needs to be steady and controllable, typically in the 15-25 psig range for most applications. Systems can use pressure reducing valves to step down from higher pressure sources, or can use dedicated low-pressure steam generators to serve this purpose.

Flow control is just as important as pressure control. Each seal point needs just enough steam to do its job – too little and you get leakage, too much and you’re wasting money. Modern systems use automatic flow control valves that adjust based on differential pressure across the seal points.

What Happens to Used Gland Steam

Here’s something that surprises a lot of new engineers: we don’t just let used gland steam escape to atmosphere. That would be wasteful and, in many places, illegal from an environmental standpoint. Instead, used gland steam goes to a gland steam condenser, where it’s condensed back to water and returned to the cycle.

The gland steam condenser is usually a small shell-and-tube heat exchanger cooled by circulating water or service water. The condensate produced is relatively pure since gland steam is clean, so it can go back to the hotwell or deaerator without treatment.

This recovery system serves multiple purposes: it captures the energy in the gland steam (remember, that steam costs fuel to produce), it eliminates visible steam plumes that can cause visibility and environmental issues, and it returns pure water to the cycle. In a well-designed system, the only thing you should see leaving the gland steam system is a small amount of air that gets pulled in and then vented from the condenser.

Normal Operation – What Should Happen

Startup Sequence

Here’s something that trips up a lot of new operators: you need gland steam established before you even think about rolling the turbine. I’ve seen people try to start without proper gland sealing, and it’s not pretty – steam everywhere, alarms going off, and a very unhappy shift supervisor.

The typical sequence goes like this: establish gland steam header pressure first, usually from the auxiliary boiler during cold startup. Check that you’re getting proper flow to all seal points and that the gland steam condenser is working. Only then do you start introducing steam to the turbine itself.

As turbine pressure builds during startup, you’ll need to adjust gland steam pressure to maintain the proper differential. This is usually automatic, but good operators watch the pressures and intervene if the controls aren’t keeping up. I always tell people to expect some steam visibility during startup – it’s normal as the system finds its balance.

Temperature buildup happens gradually, and that’s what you want. Rapid temperature changes stress the seals and can cause damage. Most startup procedures specify maximum temperature rise rates to protect the equipment.

Normal Running Conditions

During normal operation, gland steam systems are pretty stable. Header pressure typically runs 15-25 psig, seal point temperatures stay within expected ranges, and you shouldn’t see any steam leakage to the atmosphere.

The system automatically responds to load changes, but there’s usually a brief adjustment period. When you increase turbine load, pressures rise slightly, and the gland steam system adjusts to maintain sealing. Good systems make these adjustments smoothly without operator intervention.

What should operators monitor? Header pressure is the big one – it’s your best indicator of overall system health. Seal point temperatures tell you about local conditions. Flow rates help you spot developing problems before they become serious. And always keep an eye on the gland steam condenser – if it’s not working, the whole system can fail quickly.

Shutdown Process

Here’s where experience really shows: gland steam doesn’t get shut off just because you’re shutting down the turbine. In fact, it’s more critical during shutdown than almost any other time.

As turbine steam pressure drops during shutdown, you need to maintain gland steam to prevent air from being sucked into the turbine. This is especially important on LP sections that operate under vacuum. Let air get in, and you’ll be dealing with corrosion and efficiency problems for months.

The cooling down process is gradual – you want everything to cool at roughly the same rate to minimize thermal stress. Most procedures call for maintaining gland steam until turbine metal temperatures drop below about 200°F.

When is it safe to stop gland steam? Generally, when the turbine is cold, the rotor has stopped, and you’re confident there’s no pressure differential that could cause problems. Even then, many plants maintain a small amount of gland steam on critical seals to prevent moisture intrusion during extended outages.

Common Problems and Troubleshooting

I. Excessive Steam Consumption

- What You’ll See: Your steam flow meters showing higher than normal consumption, maybe 2-3 times what you expect. You might see visible steam wisps around seal areas, and your plant efficiency numbers start dropping.

- What’s Usually Wrong: Nine times out of ten, it’s either worn seal rings that aren’t making proper contact, or someone has the gland steam pressure set too high. I’ve also seen control valves stick open after maintenance, flooding the seals with excessive steam.

- Quick Checks: Walk around and look first – your eyes are often better than instruments. Check gland steam header pressure against your normal operating values. Look at individual seal point flow indicators if you have them. A sudden jump in consumption usually points to one specific location.

- How to Fix It: If pressure is high, back it down gradually while watching for any signs of leakage. Don’t drop it too fast or you’ll go from one problem to another. For worn seals, you’re looking at a planned outage for replacement – they don’t get better on their own. Stuck valves might respond to cycling them a few times, but plan on maintenance if that doesn’t work.

II. Poor Sealing Performance

- What You’ll See: Steam leaking visibly from gland areas, high temperatures on your seal housing thermocouples (usually 50°F or more above normal), and operators complaining about visibility problems around the turbine.

- What’s Usually Wrong: Low gland steam pressure is the most common culprit – you’re not providing enough pressure differential to keep turbine steam from escaping. Clogged strainers or plugged orifices can also starve individual seals of steam. Sometimes it’s as simple as a manual valve that got left partially closed after maintenance.

- Quick Checks: Check your gland steam header pressure first – it should be steady and at normal operating values. Walk the system and verify all manual valves are fully open. Look for any obvious restrictions like dirty strainers or kinked tubing. Check individual seal point pressures if you have local gauges.

- How to Fix It: Clean those strainers – you’d be surprised how often this solves the problem. Verify your pressure control valve is responding properly by slightly adjusting the setpoint and watching the response. If you have individual seal control valves, make sure they’re not hunting or stuck. Sometimes the fix is as simple as increasing gland steam pressure by 2-3 psi.

III. Gland Steam Condenser Issues

- What You’ll See: Poor vacuum in the gland steam condenser (should be 15-25 inches Hg), condensate temperatures higher than normal (usually should be within 10-15°F of cooling water temperature), or visible steam discharge from the condenser vent.

- What’s Usually Wrong: Cooling water problems are the biggest issue – either insufficient flow, high inlet temperature, or fouled tubes that can’t transfer heat effectively. Air leaks into the condenser shell will also kill performance by reducing the vacuum needed for proper condensation.

- Quick Checks: Verify cooling water flow and inlet/outlet temperatures. The temperature rise across the condenser should be reasonable – maybe 10-15°F depending on load. Check vacuum readings and compare to normal values. Look for any obvious air leaks around flanges or instrument connections.

- How to Fix It: If cooling water flow is low, check for fouled strainers or closed valves. Tube cleaning might be needed if temperature differences are off. For air leaks, soap solution around suspected areas will show you exactly where they are. Don’t forget to check the vacuum breaker valve – I’ve seen them leak and cause all sorts of condenser problems.

Basic Maintenance You Should Know

Let me share some maintenance wisdom I’ve learned the hard way over the years. Good maintenance prevents most of the problems we just talked about, and it’s a lot cheaper than emergency repairs.

Daily Checks

- Pressure and Temperature Readings: Make these part of your routine log rounds. Gland steam header pressure should be rock steady – if it’s hunting or drifting, something’s wrong. Seal point temperatures tell you about local conditions. I always tell operators that a 20°F temperature increase is worth investigating, and 50°F above normal means stop what you’re doing and figure out why.

- Visual Inspection for Leaks: Your eyes are incredibly sensitive leak detectors. Walk around the turbine during each shift and look for steam wisps, water stains, or salt deposits that indicate leakage. Small leaks have a way of becoming big leaks, so catch them early.

- Listening for Unusual Sounds: Steam leaks make noise – usually a hissing or whistling sound. Train your ear to recognize normal operating sounds so you’ll notice when something changes. I’ve found steam leaks by sound when I couldn’t see them through the steam fog.

- Checking Control Valve Operation: Watch your gland steam pressure control valve during load changes or startup. It should respond smoothly without hunting or sticking. If you have individual seal control valves, make sure they’re not cycling constantly – that usually indicates a tuning problem.

Routine Maintenance

- Cleaning Strainers and Filters: This is probably the most important routine task you can do. Dirty strainers starve seals of steam and cause most sealing problems. Check them monthly, or more often if your steam quality is questionable. A $5 strainer cleaning can prevent a $50,000 efficiency loss.

- Testing Control Valves: Exercise your pressure control valves regularly by slightly changing setpoints and watching the response. Valves that sit in one position for months tend to stick when you need them most. Document the response times and hunting behavior – trends will tell you when maintenance is needed.

- Checking Condensate Drains: Make sure steam traps are working and orifice drains aren’t plugged. Water in your gland steam lines causes all sorts of problems, from water hammer to poor sealing. If you see condensate backing up, investigate immediately.

Conclusion: Key Takeaways for New Engineers

After walking you through all these details, let me boil down what really matters for someone starting their career in power generation.

Why This Matters: Gland sealing isn’t glamorous, but it directly affects plant efficiency, safety, and profitability. Understanding these systems makes you a more valuable engineer and helps you troubleshoot problems that stump others.

Basic Troubleshooting: Start with the simple stuff – check pressures, look for obvious leaks, verify steam supply. Most problems have simple causes, but you need to know what normal looks like to spot abnormal conditions.

When to Dig Deeper: If routine adjustments don’t fix the problem, or if you’re seeing safety-related issues, don’t keep trying random solutions. Get help from experienced personnel or engineering support.

Routine Monitoring: Make gland steam checks part of your normal routine. These systems are reliable when properly maintained, but they need attention. A few minutes of daily checks can prevent hours of emergency troubleshooting.

Career Development: Understanding auxiliary systems like gland sealing builds the foundation for understanding main turbine systems. Every experienced turbine engineer started by learning these fundamentals. Master the basics, and the complex stuff becomes much easier to understand.

>>> You can strengthen your career by enrolling in training programs offered by major industry leaders like GE and Siemens.

~Rotormind