The Role of Oil Seals in Turbine Operation: Everything You Need to Know

Introduction

Inside every turbine, high-speed rotating shafts work continuously to convert energy into power. To keep these rotating parts operating smoothly and efficiently, lubrication is essential. Lubricating oil reduces friction, cools components, and protects the delicate internal parts from wear.

However, while lubrication is necessary, it also brings a serious challenge: the oil must stay inside the system. If lubrication oil leaks out, it can lead to severe problems — from bearing failures and overheating to environmental hazards and even fire risks. That’s where turbine oil seals come into play.

Oil seals serve as critical barriers within turbine systems. They prevent valuable lubricating oil from escaping, stop contaminants from entering sensitive areas, and play a key role in maintaining the overall reliability and safety of turbine operations.

Why Oil Seals Are Critical in Turbine Operation

Oil seals may seem like minor components, but they directly impact both performance and safety. Understanding why turbine oil seals are critical begins with recognizing their four fundamental purposes:

- Preventing Oil Leakage from Turbine Bearings: Turbine bearings require a constant supply of lubricating oil to reduce friction, control heat, and prevent wear. Oil seals act as the primary barrier preventing lubricating oil from escaping the bearing housing. Without effective seals, this pressurized oil would leak continuously, leading to rapid oil loss, bearing failure, and potential fire hazards from hot oil contacting turbine surfaces.

- Maintaining Lubrication System Pressure: Turbine lubrication systems are designed to operate under controlled pressure. This pressure ensures that oil reaches all the critical areas inside the turbine. If oil seals fail and allow leakage, the system pressure can drop, leading to inadequate oil distribution. Maintaining proper sealing helps the lubrication system function at its designed performance level.

- Protecting Against Contamination Entering Bearing Housing: Oil seals work bidirectionally—they not only keep oil inside but also prevent external contaminants from entering the bearing housing. Dust, moisture, and other particles can severely damage precision bearing surfaces and degrade oil quality. By maintaining a clean internal environment, seals extend bearing life and preserve lubrication system performance.

- Supporting Turbine Efficiency and Safety: Effective sealing directly contributes to overall turbine efficiency by maintaining optimal lubrication conditions and preventing energy losses associated with oil leakage. From a safety perspective, seals prevent oil from reaching hot turbine surfaces where it could ignite, and they help maintain the controlled environment necessary for safe turbine operation.

How Oil Seals Work: The Science Behind It

Understanding ‘how oil seals work’ starts with grasping surprisingly straightforward principles that become powerful when properly applied: they keep the oil inside the bearing housing and the contaminants outside. To do this, oil seals control the tiny gap between the rotating shaft and the stationary housing.

The Basic Sealing Principle

Turbine shafts rotate at very high speeds. Shaft sealing in turbine applications presents unique challenges due to high rotational speeds and extreme operating conditions. Around these shafts, oil is continuously supplied to the bearings to reduce friction and heat. Inside the turbine bearing housing, lubricating oil is maintained at higher pressure to ensure proper lubrication flow. Outside the housing, pressure is typically atmospheric or lower. The seal’s job is to prevent oil from flowing from the high-pressure side to the low-pressure side while allowing the shaft to rotate freely.

Think of it like a dam holding back water—the seal must be strong enough to resist the pressure difference but flexible enough to accommodate the moving shaft. The key is creating just enough resistance to stop unwanted flow without creating excessive friction that would generate heat or cause premature wear.

Precision Matters The effectiveness of any oil seal depends on extremely tight tolerances. If the seal is too loose, oil can leak. If it’s too tight, it can generate heat, wear out quickly, or damage the shaft.

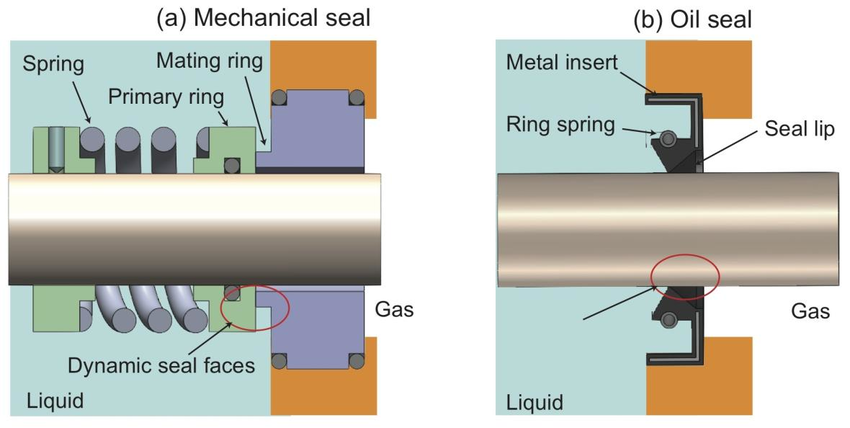

Contact vs. Non-Contact Sealing Oil seals achieve this precision through two main approaches:

Contact seals physically touch the rotating shaft, creating a direct mechanical barrier. The sealing lip or face maintains contact through spring pressure or interference fit. While this provides excellent sealing performance, it generates friction and heat, requiring careful material selection and lubrication. i.e. Carbon Ring Seals, Simple Lip Seals etc.

Non-contact seals create the barrier without touching the shaft, using precisely controlled clearances and fluid dynamics. These seals rely on the principle that oil cannot easily flow through very small, tortuous paths, especially when pressure drops across multiple stages. i.e. Labyrinth Seals.

Critical Design Factors Several factors determine seal performance:

- Clearances: Must accommodate thermal expansion, manufacturing tolerances, and shaft movement while maintaining sealing effectiveness

- Materials: Must withstand operating temperatures, chemical compatibility with oils, and wear resistance. Advanced shaft sealing technologies must account for thermal expansion and dynamic loads

- Surface finish: Affects how well the seal interfaces with the shaft and housing

- Operating speed: Higher speeds create additional challenges from centrifugal forces and heat generation

Types of Oil Seals Used in Turbine Applications

Selecting the right types of oil seals for turbine applications requires understanding how each design handles extreme operating conditions including high speeds, elevated temperatures, and significant pressure differentials. To handle these challenges, several specialized types of oil seals are used, each designed for specific applications and performance needs:

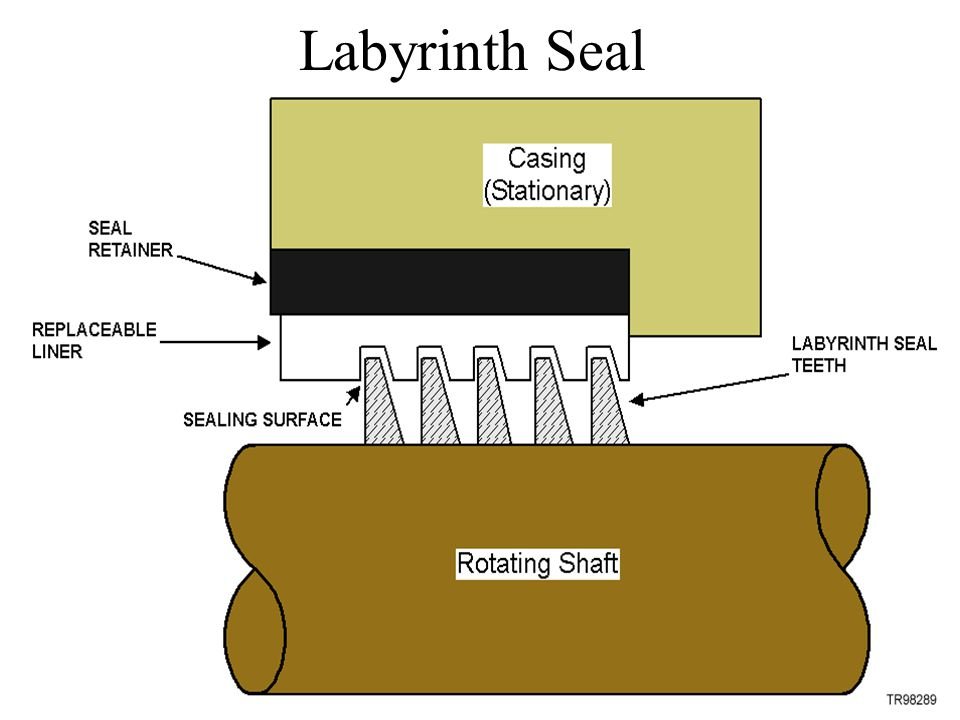

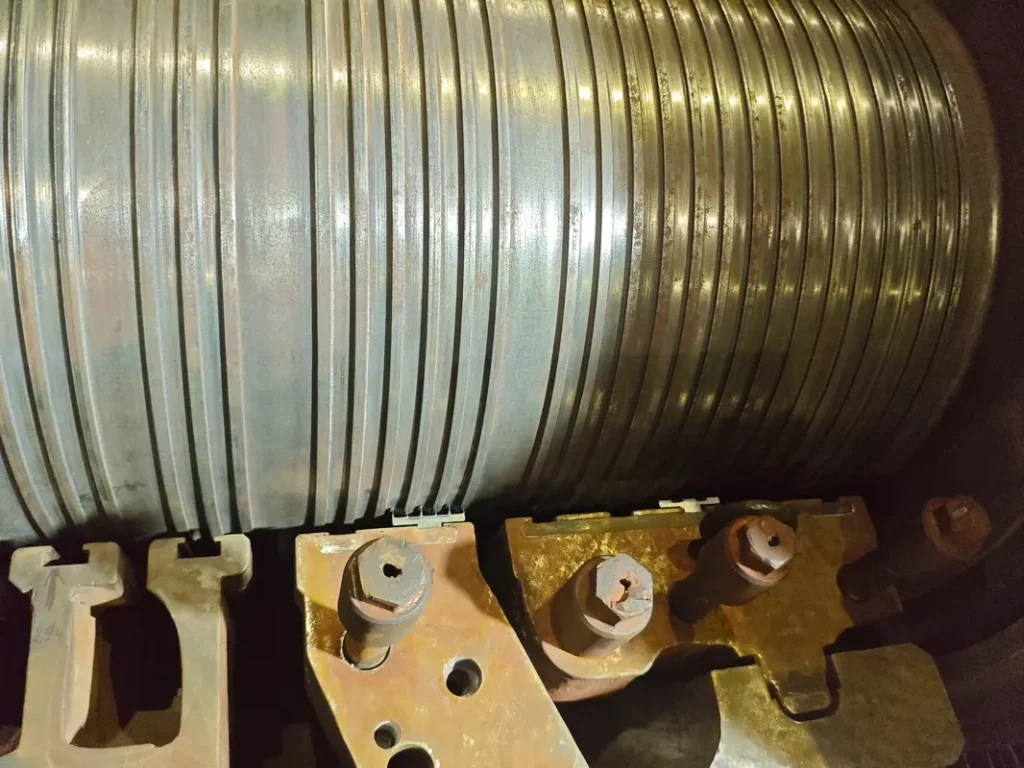

Labyrinth Seals: The High-Speed Champions

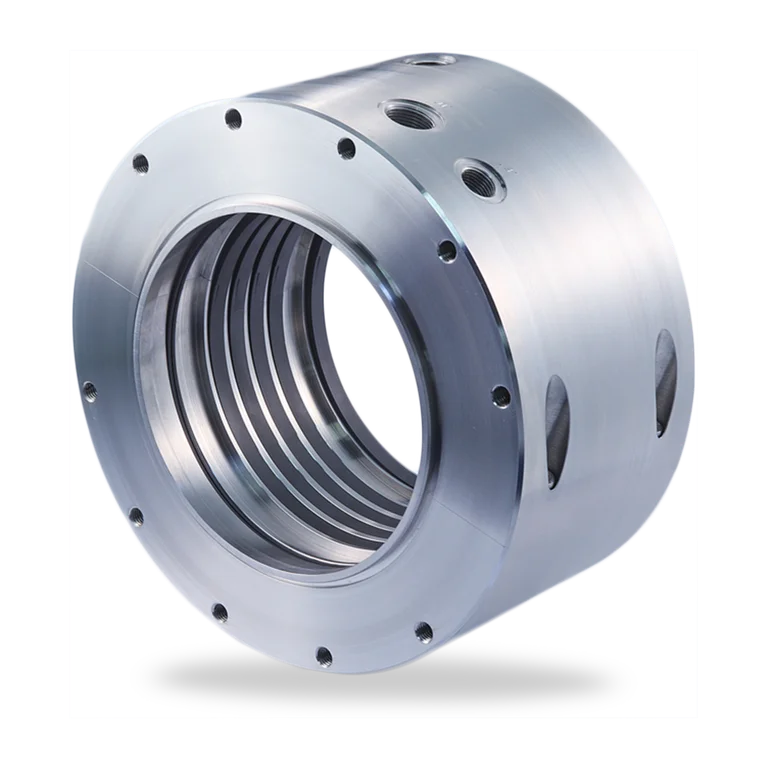

Labyrinth seals represent the engineering marvel of non-contact sealing technology, earning their place as the backbone of steam turbine shaft sealing systems worldwide. Picture a sophisticated maze carved into metal—that’s essentially what a labyrinth seal creates for any oil attempting to escape the bearing housing.

The labyrinth seal operates on a deceptively simple yet brilliant principle: it forces oil to navigate through a series of precisely machined chambers, each designed to reduce pressure and velocity. As oil enters the first chamber, it encounters a sudden expansion that causes turbulence and energy loss. The oil then must squeeze through a narrow restriction into the next chamber, where the process repeats. With each stage, the oil loses more energy and pressure until it lacks sufficient force to continue through the remaining chambers.

What makes labyrinth seal technology so remarkable is its ability to handle extreme conditions without any physical contact. The seal teeth—thin metal fins that extend toward the shaft—maintain clearances measured in thousandths of an inch. These teeth never touch the rotating shaft, eliminating friction, heat generation, and wear that plague contact-type seals. This non-contact design allows labyrinth seals to operate at shaft speeds exceeding 6,000 RPM, temperatures approaching 500°C, and pressures up to 50 bar.

The genius of labyrinth seal design lies in its forgiving nature. Unlike contact seals that fail catastrophically when clearances increase, labyrinth seals degrade gradually. A small increase in clearance results in proportionally higher leakage—manageable and predictable. This characteristic makes them ideal for critical applications where sudden seal failure could cause catastrophic turbine damage.

The primary limitation of labyrinth seal technology is its dependence on precise clearances. While forgiving compared to contact seals, significant clearance increases—often caused by thermal distortion or mechanical wear—can result in unacceptable oil leakage rates. Regular monitoring and periodic adjustment ensure optimal performance throughout the seal’s service life.

Carbon Ring Seals: The Precision Performers

Carbon ring seals represent the sophisticated middle ground between non-contact labyrinth designs and high-maintenance mechanical face seals. These seals feature multiple carbon segments arranged in a ring formation, creating a semi-contact sealing interface that combines excellent sealing performance with reasonable maintenance requirements.

Understanding how oil seals work in carbon ring applications requires appreciating the unique properties of carbon as a sealing material. Carbon offers exceptional thermal stability, maintaining its sealing properties at temperatures that would destroy rubber or polymer seals. The material’s natural lubricity allows gentle contact with rotating shafts without generating excessive heat or wear, while its ability to conform to slight surface irregularities ensures consistent sealing performance.

The carbon ring seal assembly consists of individual carbon segments held in a precision-machined housing. Spring mechanisms—either individual coil springs or continuous wave springs—provide the force necessary to maintain contact between the carbon elements and the rotating shaft. This spring-loaded design allows the seal to accommodate shaft runout, thermal expansion, and normal manufacturing tolerances while maintaining consistent contact pressure.

Operational dynamics of carbon ring seals involve a delicate balance between sealing effectiveness and heat generation. The carbon segments maintain light contact with the shaft, creating a controlled wear interface. As the carbon gradually wears to match the shaft surface, it forms a perfect sealing profile. This wearing-in process, when properly controlled, results in exceptional sealing performance with minimal ongoing wear.

Temperature management plays a crucial role in carbon ring seal performance. While carbon handles high temperatures well, excessive heat can cause thermal distortion of the seal housing or changes in spring characteristics. Adequate oil flow for cooling and lubrication is essential, particularly during startup and shutdown when thermal transients are most severe.

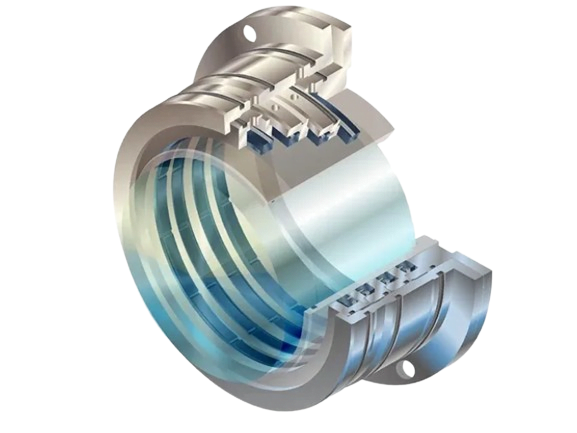

Mechanical Face Seals: The Precision Guardians

Mechanical face seals represent the pinnacle of sealing technology for applications demanding absolute leakage control. These sophisticated devices use two precisely machined and polished flat surfaces—one rotating with the shaft and one stationary—to create a sealing interface measured in light bands, achieving leakage rates often below detectable limits.

The heart of a mechanical face seal lies in its primary sealing interface: two flat surfaces maintained in contact by spring force or hydraulic pressure. The rotating face, typically made of hard materials like silicon carbide or tungsten carbide, spins with the shaft. The stationary face, often made of carbon or ceramic materials, remains fixed in the seal housing. Between these faces exists a lubricating film measured in microinches—thin enough to prevent leakage yet thick enough to prevent destructive dry contact.

Engineering precision in mechanical face seals reaches extraordinary levels. The sealing faces must be flat to within 2-3 light bands (approximately 0.000025 inches) and polished to mirror finishes. Surface roughness measurements in angstroms determine sealing performance. Even microscopic scratches or contamination particles can compromise seal effectiveness, making cleanliness during installation and operation paramount.

The primary advantage of mechanical face seals is their ability to achieve virtually zero leakage under proper operating conditions. They excel in applications where environmental regulations, safety requirements, or process considerations demand absolute containment. However, this performance comes at the cost of complexity, maintenance requirements, and sensitivity to operating conditions.

Failure modes typically involve loss of face flatness due to thermal distortion, contamination damage, or wear. Unlike labyrinth seal systems that degrade gradually, mechanical face seal failures often occur suddenly and completely. This characteristic makes condition monitoring and preventive maintenance critical for reliable operation.

Floating Ring Seals: The Balanced Solution

Floating ring seals represent an innovative approach to shaft sealing that bridges the gap between non-contact and contact seal technologies. These seals feature a ring that “floats” on a thin film of oil, creating an effective barrier while minimizing direct contact with the rotating shaft. The floating ring design allows the seal to automatically adjust to minor shaft movements and thermal expansion, making it particularly well-suited for medium-speed turbine applications.

The floating ring seal operates on the principle of controlled clearance combined with oil film lubrication. The ring is designed to maintain a precise gap with the shaft—typically 0.002 to 0.005 inches—while being supported by a pressurized oil film. This oil film serves dual purposes: it provides lubrication to minimize wear and creates a hydraulic barrier that prevents oil leakage from the high-pressure side to the low-pressure side.

What makes floating ring seals particularly effective in turbine applications is their ability to accommodate shaft runout and thermal growth without losing sealing effectiveness. Unlike rigid labyrinth seal designs that rely on fixed clearances, floating ring seals dynamically adjust to changing operating conditions. The ring can move radially to follow slight shaft eccentricity while maintaining consistent sealing performance.

Key advantages of floating ring seals include excellent sealing effectiveness at moderate speeds, self-adjusting capability for shaft irregularities, and relatively low maintenance requirements compared to mechanical face seals. They typically provide better sealing than labyrinth seal configurations while offering longer service life than conventional lip seals.

The main limitations of floating ring seals include their sensitivity to oil cleanliness—contaminated oil can cause the ring to stick or wear prematurely—and their reduced effectiveness at very high speeds where centrifugal forces can disrupt the oil film. They also require more precise manufacturing tolerances than some other types of oil seals, which contributes to their moderate cost range.

Simple Lip Seals: The Reliable Workhorses

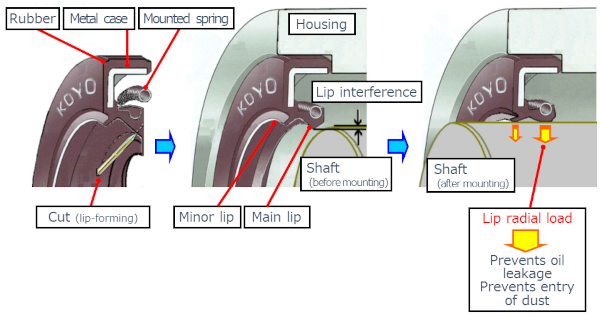

Simple lip seals represent the most straightforward approach to shaft sealing, utilizing an elastomeric lip that maintains contact with the rotating shaft through interference fit and spring pressure. While humble in design compared to sophisticated labyrinth seal or mechanical face seal systems, lip seals provide reliable, cost-effective sealing for countless low-speed turbine applications.

The fundamental design of a lip seal consists of an elastomeric sealing element—typically made from nitrile rubber, fluoroelastomer, or polytetrafluoroethylene—molded into a specific profile that creates sealing contact with the shaft. The sealing lip extends radially inward, creating an interference fit with the shaft diameter. This interference, combined with the lip’s flexibility, maintains contact as the shaft rotates while accommodating minor irregularities and thermal expansion.

Lip geometry and design significantly influence sealing performance and service life. The contact angle between the lip and shaft affects sealing pressure and heat generation. Steeper angles provide better sealing but increase friction and wear. The lip thickness determines flexibility and heat dissipation capability. Modern lip seals often incorporate multiple lips or specialized profiles to optimize performance for specific applications.

Garter springs in many lip seal designs provide additional contact force and help maintain sealing pressure as the elastomeric material wears or hardens with age. These small coil springs, encircling the seal lip, ensure consistent contact pressure regardless of thermal expansion or minor shaft eccentricity. The spring force must be carefully calibrated—too little allows leakage while too much accelerates wear.

Operating limitations of lip seals become apparent in high-speed or high-temperature applications. The contact between the elastomeric lip and rotating shaft generates heat proportional to the contact pressure and surface speed. At high speeds, this heat generation can cause thermal degradation of the seal material or thermal distortion that destroys sealing effectiveness. Most lip seals are limited to surface speeds below 2000 feet per minute.

Oil Seal Comparison Table

| Seal Type | Max Speed (RPM) | Temperature Range | Pressure Rating | Typical Life (Years) | Maintenance Level | Best Application | Approximate Cost |

|---|---|---|---|---|---|---|---|

| Labyrinth Seal | 6,000 | -40°C to 500°C | Up to 50 bar | 15-20 | Very Low | Steam turbines, high-speed shafts | $500-2,000 |

| Carbon Ring Seal | 4,000 | -20°C to 400°C | Up to 35 bar | 8-12 | Medium | Gas turbines, moderate speeds | $1,200-4,000 |

| Mechanical Face Seal | 3,500 | -10°C to 300°C | Up to 100 bar | 5-8 | High | Auxiliary equipment, pumps | $2,000-8,000 |

| Floating Ring Seal | 3,000 | -10°C to 250°C | Up to 20 bar | 6-10 | Medium | Medium-speed turbines, compressors | $800-2,500 |

| Lip Seal (Elastomeric) | 1,500 | -30°C to 150°C | Up to 5 bar | 2-4 | Very High | Low-speed applications | $50-200 |

Turbine Oil Seal Maintenance: A Systematic Approach

Proper maintenance of turbine oil seals prevents 85% of unexpected failures and extends equipment life by 40%. Here’s your step-by-step maintenance framework:

Daily Operations Checklist

Visual Inspection (5 minutes)

- Check for oil leaks around seal housings

- Listen for unusual noises or vibrations

- Verify oil level indicators are within normal range

- Document any abnormal conditions immediately

Quick Performance Checks

- Oil pressure readings at seal supply points

- Temperature readings at bearing housings

- Vibration levels using handheld analyzers

- Any visible oil mist or vapor

Weekly Maintenance Tasks

Vibration Analysis (30 minutes): Understanding how oil seals work under dynamic conditions requires tracking vibration patterns:

- Record baseline measurements for all shaft sealing locations

- Compare current readings to historical trends

- Flag any increases above 4.5 mm/s RMS for investigation

- Focus on frequency changes that indicate developing problems

Oil System Health Check

- Sample oil for visual contamination assessment

- Check filtration system performance

- Verify oil cooler operation

- Test backup oil pump functionality

Monthly Deep Maintenance

Comprehensive Oil Analysis: Different types of oil seals create distinct wear patterns in lubricating oil:

- Labyrinth seal systems: Monitor for metallic particles from rub events

- Carbon ring seals: Check for carbon dust and spring material debris

- Mechanical face seals: Look for face material contamination

- Results guide seal replacement timing and root cause analysis

Clearance Monitoring

- Measure critical labyrinth seal clearances using precision tools

- Document clearance growth trends over time

- Identify thermal expansion patterns during startup/shutdown cycles

- Adjust clearances when measurements exceed manufacturer limits

Annual Overhaul Planning

Complete Seal System Evaluation

- Remove and inspect all accessible shaft sealing components

- Measure wear patterns and document with digital photography

- Update seal specifications based on actual operating conditions

- Plan seal upgrades or modifications for improved performance

Documentation and Trending

- Compile annual seal performance reports

- Identify cost-saving opportunities through seal optimization

- Update maintenance procedures based on lessons learned

- Training updates for maintenance personnel

Maintenance Schedule Table

| Task | Frequenc-y | Duration | Personnel Required | Critical Parameters | Acceptance Criteria | Notes |

|---|---|---|---|---|---|---|

| Visual Inspection | Daily | 15 min | Operator | Oil leaks, unusual sounds | No visible leakage, normal noise levels | Use flashlight for hidden areas |

| Vibration Monitoring | Weekly | 30 min | Technician | Amplitude, frequency spectrum | <4.5 mm/s overall RMS | Record trending data |

| Oil Analysis | Monthly | 2 hours | Lab Tech | Water content, particle count, viscosity | <200 ppm water, ISO 18/16/13 cleanliness | Include wear metals analysis |

| Clearance Measurement | Quarterly | 4 hours | Specialist | Radial/axial gaps | Per manufacturer specifications | Use precision measuring tools |

| Seal Inspection | Semi-annually | 8 hours | Maintenance Team | Wear patterns, surface condition | No scoring, cracking, or excessive wear | Document with photos |

| Complete Overhaul | 3-5 years | 2-3 days | Overhaul Team | All components | Return to new condition specifications | Follow OEM procedures |

Emergency Response Procedures

Seal Failure Response (Response time: <2 hours)

- Immediate Assessment: Determine if continued operation is safe

- Isolation Procedures: Implement emergency seal oil supply if available

- Documentation: Photo/video evidence for root cause analysis

- Notification: Contact OEM technical support and management

- Temporary Measures: Install temporary sealing if possible

>>> See here for gas turbine maintenance guide in details.

Common Oil Seal Problems and Solutions

Even the best-designed oil seals can experience problems that compromise their performance. Understanding these common issues helps engineers diagnose problems quickly and implement effective solutions before minor issues become major failures.

- Wear and Tear Due to Shaft Vibration or Misalignment: Turbine shafts can experience vibration, slight movement, or misalignment during operation. This continuous motion puts extra stress on the seals, especially contact seals like carbon rings or lip seals. Over time, the constant friction can wear down the seal material, reducing its ability to maintain a tight seal.

- Solution: Regular vibration monitoring and proper shaft alignment during installation and maintenance are critical for preventing these issues.

- Seal Clearance Becoming Too Large: Over time, normal wear and thermal cycling can cause seal clearances to increase beyond acceptable limits. As clearances grow, oil leakage rates increase exponentially—a small increase in gap size can result in dramatically higher leakage. This is particularly problematic in non-contact seals like labyrinth seals, where precise clearances are essential for proper operation. Large clearances also reduce the pressure drop across the seal, further compromising its effectiveness.

- Solution: Regular inspection and measurement of seal clearances during maintenance intervals helps identify this problem before it becomes critical.

- Oil Contamination from Water Ingress or Particles: Contaminated oil can severely damage seal surfaces and reduce sealing effectiveness. Water ingress, often from cooling system leaks or condensation, can cause seal materials to swell, corrode, or lose their sealing properties. Particulate contamination acts like an abrasive, accelerating wear of both the seal and shaft surfaces. Contaminated oil also loses its lubricating properties, increasing friction and heat generation in contact seals.

- Solution: Maintaining clean, dry oil through proper filtration systems and regular oil analysis is essential for seal longevity.

- Improper Installation or Maintenance: Common installation mistakes like incorrect clearance settings, improper torque specifications, damaged sealing surfaces, or contamination during assembly can cause seal failures. Maintenance errors such as using incorrect tools, failing to replace worn components, or inadequate cleaning procedures can also lead to premature failure.

- Solution: Following manufacturer specifications and established procedures during installation and maintenance is crucial for reliable seal performance.

- Seal Hardening Due to Heat: Excessive heat exposure can cause seal materials to harden and lose their flexibility, particularly affecting rubber and elastomeric seals. Heat can result from inadequate lubrication, excessive friction, high operating temperatures, or cooling system failures. Hardened seals cannot accommodate normal shaft movement and thermal expansion, leading to cracking, leakage, and eventual failure.

- Solution: Temperature monitoring and ensuring adequate cooling and lubrication are essential for preventing heat-related seal degradation.

Recognizing these common problems and their root causes enables maintenance teams to implement preventive measures and troubleshoot issues effectively, ultimately extending seal life and improving overall turbine reliability.

Real-World Case Studies: Learning from Turbine Oil Seal Experiences

Case Study 1: Steam Turbine Labyrinth Seal Optimization

A 300 MW steam turbine at a combined-cycle power plant experienced increasing oil consumption despite recent major maintenance. Investigation revealed that labyrinth seal clearances had grown beyond specification due to thermal distortion during rapid startup cycles.

The Problem: The plant’s turbine oil seals were consuming 15 gallons of oil per day, compared to the normal rate of 2-3 gallons. Operators noticed oil mist around the turbine during operation, raising both environmental and safety concerns. Understanding how oil seals work in thermal cycling conditions became critical to solving the problem.

Root Cause Analysis: Detailed measurements showed that labyrinth seal clearances had increased from the design specification of 0.015 inches to over 0.025 inches at several locations. The excessive clearances resulted from thermal bowing of the rotor during rapid startups, causing rubbing between the labyrinth seal teeth and the rotor surface.

Solution Implementation: The maintenance team implemented a three-part solution focusing on different types of oil seals performance optimization:

- Rotor surface restoration and labyrinth seal clearance adjustment

- Modified startup procedures to reduce thermal shock

- Enhanced monitoring system for early detection of clearance changes

Results: Oil consumption dropped to 1.5 gallons per day within two weeks of the modifications. The plant avoided an estimated $180,000 in annual oil costs and eliminated environmental compliance concerns. More importantly, the improved shaft sealing performance contributed to better overall turbine efficiency.

Case Study 2: Gas Turbine Carbon Ring Seal Failure Prevention

A natural gas processing facility’s 45 MW gas turbine experienced repeated carbon ring seal failures, resulting in three unplanned shutdowns over six months. Each failure cost approximately $250,000 in lost production and emergency maintenance.

The Challenge: Traditional turbine oil seals maintenance approaches weren’t preventing the recurring failures. The facility needed to understand why their shaft sealing system was failing despite following manufacturer recommendations.

Investigation Findings: Advanced vibration analysis revealed that slight misalignment between the turbine and compressor was creating dynamic loads that exceeded the carbon ring seals’ design limits. The misalignment was too small to detect through standard alignment procedures but significant enough to cause premature seal wear.

Innovative Solution: Rather than simply replacing the failed seals, the team redesigned the shaft sealing approach by:

- Implementing laser alignment verification procedures

- Upgrading to a hybrid seal design that combined labyrinth seal elements with carbon rings

- Installing continuous monitoring systems for early failure detection

Long-term Impact: The enhanced approach eliminated seal failures for over 18 months of operation. The facility’s maintenance team gained valuable expertise in advanced types of oil seals applications, leading to similar improvements on other turbine units. Understanding how oil seals work under dynamic loading conditions enabled them to prevent similar problems across their entire fleet.

These case studies demonstrate that successful turbine oil seals management requires combining technical understanding with practical problem-solving skills, proving that investment in proper sealing technology pays dividends through improved reliability and reduced operating costs.

>>>See GE’s case study here.

Conclusion

Oil seals may seem like simple components, but their role in turbine operation is absolutely critical. As we’ve explored throughout this guide, these precision-engineered elements serve as the guardians of turbine safety and performance, preventing dangerous oil leakage while maintaining the lubrication systems that keep massive rotating machinery running smoothly.

The impact of effective sealing extends far beyond just containing oil. Well-functioning seals directly translate to fewer unplanned shutdowns, reduced maintenance costs, and improved overall efficiency. Good sealing equals operational excellence. By preventing oil leakage, maintaining proper lubrication system pressure, and protecting against contamination, quality seals enable turbines to achieve their design performance levels. This translates to better fuel efficiency, reduced emissions, and longer equipment life—benefits that compound over the years of operation.

For engineers, technicians, and maintenance professionals working with turbine systems, understanding oil seals is not just technical knowledge—it’s a pathway to career advancement and operational success. The principles we’ve covered here form the foundation for diagnosing problems, optimizing performance, and preventing failures before they occur.

Remember: in the complex world of turbine operation, mastering the fundamentals—like oil seals—is often the key to solving the most challenging problems and achieving exceptional performance.

~Rotormind

One Comment

Comments are closed.