Adsorption Dryers Explained: How Desiccant Air Dryers Work in Compressed Air Systems

Introduction to Moisture Problems in Compressed Air

”Why moisture is problematic in compressed air systems?”

Atmospheric air always contains water vapor. When we compress ambient air, we’re essentially forcing all that water vapor into a much smaller space. Here’s what happens: air at atmospheric pressure might comfortably hold, say, 10 grams of water per cubic meter. But when you compress that same air to 7 bar (a typical working pressure), it can only hold about 1.4 grams per cubic meter. So, what happens to the remaining 8.6 grams of water? Because you’re squeezing the air, giving it no space to breath, the excess water has nowhere to go except to condense out as liquid droplets.

This creates a domino effect of problems. First, you get liquid water flowing through your air lines – imagine trying to run precision pneumatic equipment with water droplets constantly hitting the components. The water causes corrosion in steel pipes and can freeze in cold weather, potentially blocking your entire air system. Pneumatic actuators and cylinders experience seal failures when water washes away their lubricants, leading to expensive downtime. The real-world impact of wet compressed air goes beyond just equipment damage – it hits your production quality and bottom line. For young engineers, remember this simple rule: wherever you see compressed air, expect condensation unless you actively prevent it.

So, dryers are essential in any compressed air system because moisture in compressed air can lead to serious problems. By removing water vapor before it enters the air network, dryers protect downstream components, extend equipment life, and ensure consistent performance, especially in critical applications like power plants, pharmaceuticals, and food processing. In this comprehensive guide, we’ll explore different types of drying technologies, why adsorption dryer is best suited for reliability, working principles of adsorption dryer, real-world illustrations of adsorption dryer (Ingersoll Rand Adsorption Dryer), and common issues with troubleshooting regarding this vital auxiliary component in a power plant.

Different Air Drying Technologies: Why Adsorption Drying Is Preferred

Industrial air drying isn’t one-size-fits-all. Different applications need different moisture levels, and each technology has its sweet spot. Let’s break down the main approaches.

- Refrigerated dryers work like your home air conditioner. They cool the compressed air to about 2-4°C, causing water to condense out, then reheat it to prevent downstream condensation. They’re energy-efficient and great for general industrial use, achieving dew points around +3°C. Think of them as the workhorse solution for most applications.

- Deliquescent dryers use salt tablets that absorb moisture from the air. They’re simple, require no electricity, but create a brine solution that needs disposal. They’re mainly used in remote locations or as backup systems.

- Membrane dryers use selective permeation – water vapor passes through special hollow fibers while dry air continues downstream. They’re compact, have no moving parts, and work well for smaller flow rates or point-of-use applications.

- Adsorption dryers use desiccant materials (like activated alumina or molecular sieves) that physically grab water molecules from the air. They can achieve extremely low dew points (-40°C to -70°C) and are the gold standard when you need really dry air.

Think I meant ‘absorption’? Think again. ‘Adsorption’ and ‘Absorption’ aren’t typos — they’re two entirely different kinds. ‘Adsorption’ type dryers are also called ‘Desiccant’ type as they use desiccant materials (silica gel, activated alumina etc.) to remove moisture from compressed air.

Why adsorption drying is preferred for ultra-dry air requirements?

When you need air drier than what refrigerated dryers can provide, adsorption technology becomes your go-to solution. Adsorption dryers don’t rely on cooling to remove moisture – they use desiccant materials that have an almost magnetic attraction to water molecules. This means they can pull moisture out of air even when it’s already very dry.

The key advantage is the dew point they can achieve. While a refrigerated dryer stops at around +3°C dew point (limited by ice formation), adsorption dryers routinely reach -40°C or even -70°C dew points. This ultra-dry air is essential for applications like:

- Instrument air systems where precise control depends on consistent, dry air

- Pharmaceutical manufacturing where even trace moisture can degrade products

- Electronics assembly where humidity causes component failures

- Pneumatic conveying of hygroscopic materials that clump when exposed to moisture

Many industries require compliance with specific air quality standards to ensure safe and efficient operation, such as those outlined by ISO and other regulatory bodies.

- ISO 8573-1 Class 1 for particles, water, and oil

- FDA 21 CFR Part 11 for pharmaceutical applications

- HACCP requirements for food processing

The only trade-off is energy consumption and complexity. Adsorption dryers need energy to regenerate their desiccant beds, and they require more sophisticated controls. But when process failure isn’t an option, adsorption drying is often the only technology that can deliver the required air quality consistently and reliably.

What is an Adsorption Dryer?

Definition and Basic Concept

An adsorption dryer is a compressed air treatment system that removes moisture by using solid desiccant materials that attract and hold water molecules on their surface. Think of it like a molecular-level magnet for water – the desiccant material has countless tiny pores and surface sites that water molecules stick to, leaving the air stream dry.

The beauty of this system lies in its simplicity: wet compressed air flows through a bed of desiccant beads, the water molecules get trapped on the surface of these beads, and dry air continues downstream. Unlike other drying methods that rely on temperature changes or physical barriers, adsorption works purely through molecular attraction forces between the water and the desiccant material.

Difference Between Adsorption and Absorption

Many engineers confuse these two terms, but the difference is crucial for understanding how these dryers work:

| Aspect | Adsorption | Absorption |

|---|---|---|

| Process | Water molecules stick to the surface of the desiccant | Water molecules are absorbed into the bulk of the material |

| Physical change | Surface phenomenon – molecules form a thin layer | Bulk phenomenon – molecules penetrate throughout the material |

| Capacity | Limited by surface area of the desiccant | Limited by volume of the absorbing material |

| Reversibility | Easily reversible by heating (regeneration) | Often irreversible or requires chemical treatment |

| Material examples | Activated alumina, silica gel, molecular sieves | Salt tablets, calcium chloride, lithium chloride |

| Industrial use | Compressed air dryers, gas purification | Deliquescent dryers, humidity control |

| Energy for regeneration | Low to moderate heating (120-200°C) | Often requires complete replacement |

The key takeaway: Adsorption dryers work by sticking water to surfaces, making them easy to regenerate. Absorption dryers soak up water like a sponge, often requiring material replacement.

Role of Desiccants in Moisture Removal

Desiccants are the workhorses of adsorption dryers, and choosing the right one is critical for performance. Here’s how they function and what makes them effective:

- Activated Alumina is the most common choice for compressed air applications. It’s essentially aluminum oxide with a highly porous structure – imagine a piece of material the size of a marble having the surface area of a football field. This massive surface area gives it excellent water-holding capacity. It works well at typical compressed air temperatures and its regeneration characteristics are predictable, typically requiring 4-6 hours at 350-400°F for complete moisture removal.

- Silica Gel excels at lower humidity levels and has a very high affinity for water. It’s often used in applications where you need to reach extremely low dew points. The regeneration temperature is moderate, making it energy-efficient. However, silica gel requires careful handling due to its tendency to generate dust particles when subjected to excessive vibration or thermal cycling.

- Molecular Sieves are the precision tools of the desiccant world. For critical applications requiring pressure dew points below -100°F, molecular sieves represent the gold standard. They have uniform pore sizes that can selectively capture water molecules while allowing other gases to pass through. They’re essential when you need both ultra-low dew points and can’t afford any contamination. The material’s regeneration temperature requirements are higher (typically 500-600°F), but the performance consistency justifies the increased energy consumption.

Desiccant Selection Criteria: Proper desiccant selection requires balancing multiple factors- required dew point, operating pressure, temperature range, cycling frequency, and contaminant tolerance. Economic considerations include initial cost, regeneration energy requirements, and replacement frequency. I always recommend conducting pilot testing with actual plant conditions before committing to large-scale installations.

Fundamental Working Principles

How Desiccants Attract and Hold Water Molecules

The magic of adsorption happens at the molecular level through Van der Waals forces – weak attractive forces between molecules. Picture the desiccant material as a city with millions of tiny parking spaces (called adsorption sites) where water molecules can dock. When wet compressed air flows through the desiccant bed, water molecules are naturally drawn to these sites and stick to the surface.

The process is surprisingly selective. Water molecules have a strong dipole moment (they’re electrically unbalanced), making them highly attracted to the polar sites on desiccant surfaces. Meanwhile, the main components of air (nitrogen and oxygen) are non-polar and largely ignore these sites, passing through unchanged. This selectivity is why adsorption dryers can remove water without affecting the air’s other properties.

Physical vs. Chemical Adsorption

Physical adsorption (physisorption) is what happens in most compressed air dryers. Water molecules stick to the desiccant surface through weak Van der Waals forces. Easy to attach, easy to remove. The water molecules retain their chemical identity and can be easily released by heating the desiccant to 120-200°C. This reversibility is why we can regenerate the desiccant hundreds of times.

Chemical adsorption (chemisorption) involves actual chemical bonds forming between the water and desiccant. This bond is much stronger. While this provides excellent water removal, it’s largely irreversible under normal regeneration conditions. Some specialized desiccants use chemisorption for ultra-critical applications, but they typically require much higher regeneration temperatures or complete replacement.

For standard compressed air applications, physical adsorption is preferred because it’s energy-efficient and allows for long desiccant life.

Saturation Point and Regeneration Necessity

Every desiccant has a saturation point – the maximum amount of water it can hold. Think of it like a parking garage that eventually fills up. As the desiccant approaches saturation, three things happen:

- Reduced efficiency: The remaining empty sites become harder for water molecules to reach

- Breakthrough: Water starts passing through without being captured

- Performance degradation: The outlet dew point begins to rise

This is why regeneration is essential. The regeneration process is what makes adsorption dryers practical for continuous operation. When the desiccant becomes saturated with water, hot air (or sometimes just dry air under vacuum) is passed through the bed. The heat breaks the molecular bonds holding the water to the desiccant surface, and the water is carried away, leaving the desiccant ready for another cycle. A properly designed system will regenerate the desiccant before it reaches saturation, maintaining consistent performance.

Pressure and Temperature Effects on Adsorption

Two key engineering principles govern adsorption performance:

Pressure effects: Higher pressure increases adsorption capacity. This works in our favor because compressed air systems operate at elevated pressures (typically 7-10 bar). The increased pressure literally pushes more water molecules into contact with the desiccant surface. However, there’s a trade-off – higher pressure also means more energy is needed for regeneration.

Temperature effects: Lower temperatures favor adsorption, higher temperatures favor desorption. This is why adsorption dryers work best when the compressed air is cooled before entering the desiccant bed. During regeneration, we reverse this by heating the desiccant to release the captured water. The typical regeneration temperature range is 120-200°C – hot enough to drive off water, but not so hot that it damages the desiccant.

Twin Tower Design Concept: Why Two Towers Are Needed

The fundamental challenge of adsorption drying is that you need continuous dry air output, but the desiccant periodically needs regeneration. A single tower would mean shutting down the entire system every few hours for regeneration – completely impractical for industrial applications.

The twin tower solution is elegant: while one tower is drying the compressed air (adsorption mode), the other is being cleaned and prepared for the next cycle (regeneration mode). This allows for continuous operation with uninterrupted dry air supply. It’s like having two workers on alternating shifts – one is always on duty while the other rests and prepares.

Continuous Operation Principle

The beauty of the twin tower design lies in its seamless operation. Here’s how it works:

Tower A (right) in service: Compressed air flows through Tower A, where the desiccant removes moisture. Clean, dry air exits to the distribution system.

Tower B (left) regenerating: Simultaneously, Tower B (which was previously removing moisture and is now saturated) is being regenerated. Hot air flows through it in the opposite direction, carrying away the captured moisture.

Automatic switching: After a predetermined time (typically 4-10 minutes for heatless dryers, 1-2 hours for heated dryers), the system automatically switches roles. Tower B takes over drying duties while Tower A regenerates.

This cycle repeats continuously, providing uninterrupted dry air to your system.

Switching Mechanism Between Towers

The switching process is controlled by a sequence of pneumatic valves that must operate in precise coordination:

- Preparation phase: The regenerating tower completes its cycle and begins cooling down

- Pressure equalization: Both towers are brought to the same pressure (explained below)

- Valve switching: In a carefully timed sequence, the inlet and outlet valves switch the airflow path

- Regeneration start: The tower that was previously drying now begins its regeneration cycle

Modern systems use programmable controllers with built-in safety interlocks to ensure the switching happens smoothly without pressure spikes or interruptions to the dry air supply.

Pressure Equalization Process

This is one of the most critical aspects of twin tower operation that young engineers often overlook. When switching between towers, you can’t simply open valves between a high-pressure tower (7 bar) and a low-pressure tower (near atmospheric). The resulting pressure shock would:

- Damage the desiccant bed

- Create pressure spikes in the system

- Potentially cause valve damage

Instead, the system uses pressure equalization. Before switching, both towers are connected through a small valve that slowly brings them to the same pressure. This typically takes 1-2 minutes and ensures smooth, shock-free switching.

The pressure equalization process also serves another purpose: it helps prepare the regenerated tower for immediate service by bringing it up to working pressure gradually, allowing the desiccant bed to settle and stabilize before taking on the full airflow load.

Filtration Components

Effective filtration protects the desiccant bed and ensures consistent dryer performance throughout its operational life.

Pre-filtration Requirements: Pre-filtration serves as the first line of defense against contaminants that could poison or mechanically damage the desiccant bed. Compressed air entering the dryer typically contains oil carryover, particulates, and liquid water condensate. Without proper pre-filtration, these contaminants reduce desiccant effectiveness and create channeling paths that compromise moisture removal efficiency.

Coalescing Filters for Oil and Water Removal: High-efficiency coalescing filters remove both oil aerosols and water droplets down to 0.01 microns. These filters utilize multi-stage media to capture progressively smaller particles while allowing coalesced liquids to drain continuously. Proper sizing ensures minimal pressure drop while maintaining filtration efficiency. In my experience, oversized coalescing filters provide better long-term performance than minimum-sized units, particularly in applications with variable contamination levels.

Particle Filters for Dust Protection: Particle filtration protects desiccant materials from abrasive wear and prevents dust accumulation that could create preferential flow paths. Five-micron particle filters effectively remove pipe scale, rust particles, and atmospheric dust while maintaining reasonable pressure drop. The filter housing design must accommodate easy element replacement without system shutdown, minimizing maintenance impact on production operations.

Post-filtration Considerations: Post-filtration addresses any desiccant dust generation and provides final polishing before distribution to plant equipment. While high-quality desiccants produce minimal dust, mechanical vibration and thermal cycling can generate fine particles over time. Final filtration also serves as insurance against any upstream filter breakthrough, ensuring consistent air quality to sensitive pneumatic equipment.

Real-World Illustration: Operation Process

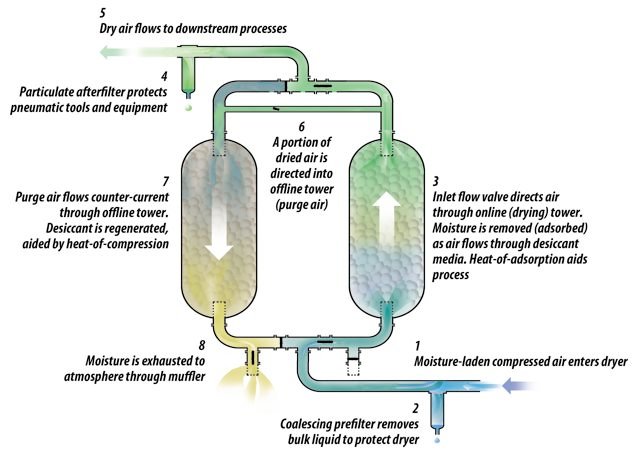

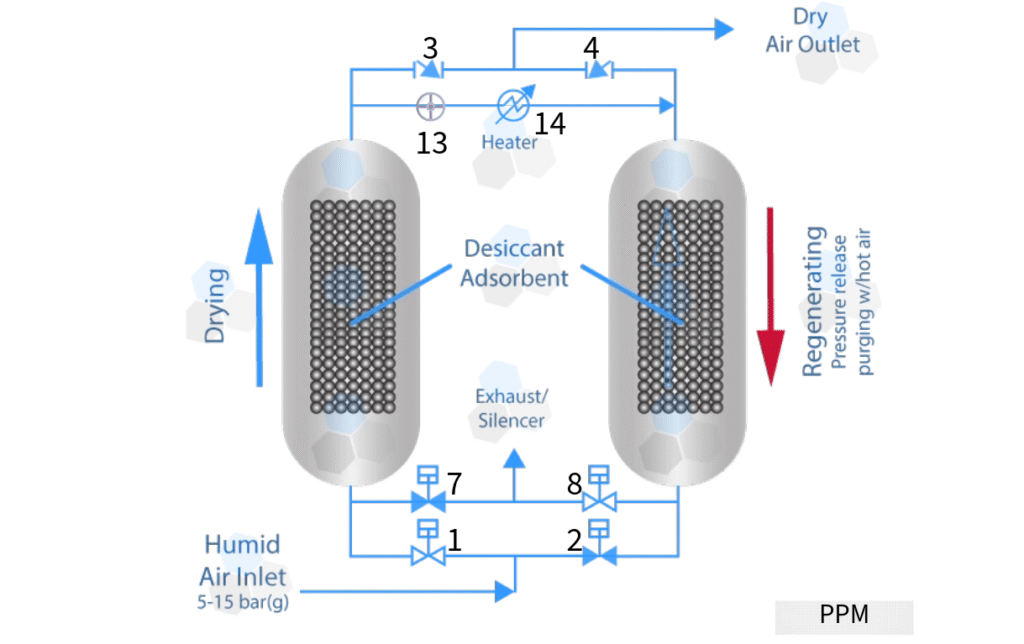

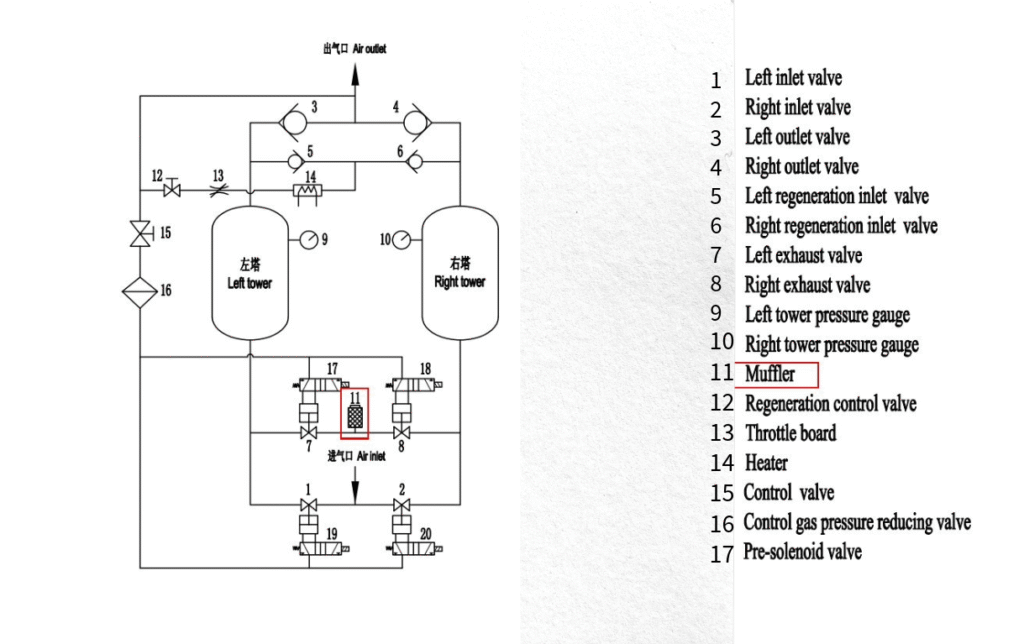

Looking at this twin-tower adsorption dryer (Ingersoll Rand) schematic, I’ll explain the operation process from a practical standpoint:

- Suppose, the left tower is adsorbed, and the right tower is regenerated.

- Start running. The left inlet valve 1 is open. Compressed air enters the left tower for adsorption and drying, and enters the pipe distribution network through valve 3.

- Simultaneously, the right tower undergoes regeneration. The right inlet valve 2 is closed, isolating it from the main air stream.

- A part of the dry gas after the drying of the left tower, goes through throttle device 13. Throttle device 13 adjusts the compressed air pressure close to the atmospheric pressure.

- The air after the pressure change expands rapidly, goes through the heater 14 and passed into the right tower (as valve 4 is closed). This expanded and heated air becomes very dry, taking away the moisture adsorbed in the right tower desiccant and aiming for valve 8.

- Valve 8 opens for pressure relief of right tower by draining out the moisture from the desiccant.

- Due to the heating, regeneration air consumption is reduced.

- The right tower adsorption, the left tower regeneration is similar to the first half of the cycle.

Performance Factors

Factors Affecting Dryer Performance

Understanding the variables that impact adsorption dryer performance is crucial for maintaining consistent moisture removal efficiency throughout the equipment’s operational life.

- Inlet Air Temperature and Pressure Effects: Higher inlet temperatures reduce desiccant adsorption capacity significantly. For every 20°F increase above design conditions, expect approximately 15-20% reduction in moisture removal capability. Conversely, higher operating pressures improve performance- it drives more aggressive moisture adsorption. I’ve observed that systems operating at 125 psig consistently outperform those at 100 psig when handling identical moisture loads.

- Flow Rate Impact on Dew Point Achievement: Flow rate directly affects contact time between air and desiccant. Higher flow rate reduces residence time, leading to moisture breakthrough and higher outlet dew points. The relationship isn’t linear – a 20% flow increase might result in 40-60% reduction in drying efficiency. Always maintain operation within 85-100% of design flow for optimal performance.

- Contamination Effects: Oil contamination creates the most severe performance degradation. Oil films coat desiccant surfaces, blocking moisture adsorption sites and creating permanent capacity loss. Particulate contamination causes mechanical abrasion and channeling, while liquid water carryover can cause thermal shock during regeneration, leading to desiccant fracturing.

- Ambient Temperature Considerations: Ambient temperature affects regeneration efficiency and cooling performance. After regeneration completes, the heated desiccant bed must cool down before it can effectively adsorb moisture again. High ambient temperatures extend cooling times, potentially causing moisture carryover during tower switching. In desert installations, I’ve seen cooling periods extend from 2 hours to 4 hours during summer months.

Common Issues and Troubleshooting

Performance Problems

I. High Outlet Dew Point

- Symptoms: Dew point readings above specification, moisture breakthrough, downstream equipment corrosion

- Common Causes:

- Insufficient regeneration time or temperature

- Contaminated desiccant reducing adsorption capacity

- Valve leakage allowing wet air bypass

- Incorrect switching timing

- Solutions:

- Check regeneration temperature profiles (should reach 350-400°F)

- Verify purge flow rates and timing

- Test valve sealing with ultrasonic leak detection

- Adjust switching cycles based on actual moisture loading

II. Premature Desiccant Saturation

- Symptoms: Rapid dew point degradation, shortened cycle times, frequent regeneration required

- Common Causes:

- Upstream oil or water contamination

- Operation beyond design flow rates

- Inadequate pre-filtration

- Excessive inlet moisture loading

- Solutions:

- Upgrade upstream filtration systems

- Monitor inlet conditions continuously

- Replace contaminated desiccant (oil contamination is irreversible)

- Verify operating parameters within design limits

III. Excessive Purge Air Consumption

- Symptoms: High compressed air usage, increased energy costs, audible air discharge

- Common Causes:

- Stuck-open regeneration valves

- Incorrect pressure settings on control valves

- Internal valve seat damage

- Solutions:

- Install flow meters on purge lines (should be 10-15% of rated capacity)

- Check regeneration valve operation during switching cycles

- Calibrate pressure reducing valves

- Replace damaged valve components

IV. Pressure Drop Issues

- Symptoms: Reduced system pressure, increased compressor loading, poor downstream performance

- Common Causes:

- Clogged filters or desiccant bed fouling

- Valve malfunctions or restrictions

- Desiccant bed channeling or settling

- Solutions:

- Monitor differential pressure across each component

- Replace filter elements at 80% of maximum pressure drop

- Inspect desiccant bed for channeling or contamination

- Check valve positions and internal restrictions

Mechanical Problems

I. Valve Operation Failures

- Symptoms: Incomplete switching, continuous air discharge, pressure fluctuations

- Common Causes:

- Pneumatic actuator seal failure

- Contaminated instrument air supply

- Worn valve seats or internal components

- Control signal problems

- Solutions:

- Maintain spare actuator assemblies for critical valves

- Install instrument air filtration and drying

- Test valve operation during scheduled maintenance

- Verify control signal integrity and calibration

II. Control System Malfunctions

- Symptoms: Erratic switching timing, false alarm conditions, poor dew point control

- Common Causes:

- Sensor calibration drift or contamination

- Wiring problems or loose connections

- Software corruption or programming errors

- Power supply issues

- Solutions:

- Establish regular sensor calibration schedules

- Maintain spare sensor inventory (dew point, temperature, pressure)

- Document all programming changes and maintain backups

- Install UPS systems for critical control components

III. Desiccant Contamination and Replacement

- Symptoms: Discolored desiccant, excessive dust generation, poor adsorption performance

- Visual Indicators:

- Oil contamination: darker color, visible residue, oily smell

- Water damage: fracturing, excessive fines, white residue

- Particulate contamination: foreign material embedded in bed

- Solutions:

- Complete bed replacement for oil contamination (cannot be regenerated)

- Proper disposal following environmental regulations

- Never mix different desiccant types in same vessel

- Install temporary filtration during replacement to prevent dust carryover

IV. System Pressure Issues

- Symptoms: Pressure fluctuations during switching, inadequate regeneration pressure, safety valve operation

- Common Causes:

- Valve timing problems during tower switching

- Inadequate pressure equalization between towers

- Regeneration pressure control valve malfunction

- System leaks or restrictions

- Solutions:

- Monitor pressure profiles during complete switching cycles

- Adjust pressure equalization timing

- Calibrate regeneration pressure reducing valves

- Conduct regular leak surveys of all pressure boundaries

Maintenance and Best Practices

Routine Maintenance Requirements

Staying ahead with routine checks ensures dryer reliability:

- Desiccant Replacement:

Replace every 1–3 years or sooner if dew point consistently fails. Avoid delay — degraded desiccant affects the whole system. - Filter Replacement:

Prefilters and afterfilters need yearly replacement or sooner if pressure drop increases. - Leak Detection:

Use ultrasonic detectors or soap solution to catch leaks, especially at joints and valves. Even small leaks waste valuable dry air. - Performance Monitoring:

Log dew point, cycle times, and pressures weekly. Abnormal trends are early warnings of internal problems.

Preventive Maintenance Strategies

Preventive maintenance is far more cost-effective than reactive repair:

- Upstream Filtration:

Always use coalescing filters and water separators to protect the desiccant. - Regular Inspections:

Visually inspect valves, hoses, electrical panels, and drain systems monthly. - Desiccant Storage:

Store new desiccant in airtight containers in dry environments — moisture exposure before installation ruins effectiveness. - Documentation:

Keep accurate logs of maintenance work, part replacements, and performance issues. It helps in diagnostics and audit readiness.

Conclusion and Key Takeaways

After decades of working with compressed air systems across various industries, I can confidently state that adsorption dryers represent one of the most reliable and cost-effective solutions for moisture removal in critical applications.

Decision-Making Guidelines for Engineers When evaluating adsorption dryers for your compressed air system, consider these critical factors:

- Required Dew Point: Match technology to actual requirements – don’t over-specify and waste energy on unnecessary performance

- Flow Variability: Systems with highly variable demand benefit from dew point controlled operation versus fixed timer cycles

- Contamination Levels: Invest heavily in upstream filtration – it’s always cheaper than premature desiccant replacement

- Total Cost of Ownership: Include energy costs, maintenance requirements, and desiccant replacement in economic analysis

- Integration Requirements: Consider how the dryer interfaces with existing compressed air treatment equipment

The fundamentals remain constant – proper design, quality installation, and proactive maintenance ensure reliable moisture removal for decades. However, the tools and technologies available to achieve these fundamentals continue improving, offering opportunities for enhanced performance and reduced operating costs.

Remember that every compressed air system is unique. What works perfectly in one application may require modification for another. Always consider the specific requirements, operating conditions, and economic constraints of each installation when making equipment selections and design decisions.

~Rotormind